|

|

| Meeting NHL Standards for Large Spectator Ice Arenas | ||||||

|

||||||

The impact of water vapor on ice surfaces has been a definite target for the Recreational Arena (Less than 2500 seats). These venues have utilized desiccant dehumidification to maintain optimum humidity levels for the best ice quality while maintaining an energy effective environment. Spectator Arenas (2500 Seats or More) have generally used traditional mechanical systems that rely on refrigerant based cooling for dehumidification and a reheat system for temperature control. The design conditions were generally 70°F at 50 % RH (Relative Humidity). Recently the NHL has issued revised design parameters to improve ice sheet and arena conditions for professional hockey venues. New modern arena construction has included active desiccant dehumidification to provide 65°F at 35% to 40% RH (Relative Humidity) conditions to optimize the ice conditions.

The recreational market (Less than 2500 Seats) has used desiccant dehumidification exclusively to maintain low dew-points. The small rink market tends to allow the rink surface to cool the arena. Many arenas run with ambient temperatures of 55°F or lower. The ARID-Ice gas fired desiccant unit we can actively maintain rink dew-points of 35°F. This benefits rink owners and operators by providing a fog and condensation free building. Eliminating condensation will enhance the building appearance and safety by eliminating mold growth on cold surfaces and providing dry, clean seats and stairs. Transferring the latent load to the gas fired dehumidifier can in many cases reduce the operating cost of the large electric rink refrigeration system. |

The applications for the ARID-Ice dehumidification system revolve around the surface temperature of the ice sheet. The brine or refrigeration system which cools the ice must deliver refrigerant cold enough to provide an ice surface temperature of 20 to 24°F. Generally this brine is circulated at 10 to 16°F to provide the required capacity. Ice sheet manufacturers provide capacity based on a heat load per square foot of ice sheet. The higher the load the lower required temperature of the supply brine and the larger the equipment and the energy cost. As the heat load rises it also takes longer to refreeze the ice surface after the resurfacing operation. In some professional or play off events, when the ambient outdoor moistures levels rise, play has had to be suspended or canceled due to areas of fog and poor ice conditions. Complaints from the players or media can put a negative spin on the level of play due to "slushy or wet" ice conditions. In the recreational rink market the dew-point of the rink is maintained at or below 32°F, This will provide an indoor condition of 55 to 60°F at 40 to 35% RH. The National Hockey League (NHL) has now issued requirements that are similar to the recreational market. The NHL has requested a 60°F at 35% pre-game condition and a 65°F at 45% post game condition. By maintaining a controlled humidity the ice surface can be optimized to provide the participants the best possible ice surface for the event. It is not surprising that these conditions are now recommended, most of the professional players practice in a recreational rink that is properly controlled. If the humidity levels rise high enough the capacity of the rink refrigeration equipment can be overrun by the latent capacity of the air and areas of liquid water can be seen on the ice sheet. It is critical for the designer to design the HVAC/DH system to provide a proper humidity in the arena to allow the event to play on the best possible surface. Following is a comparison of energy and equipment necessary to properly maintain ice event conditions in accordance with the new requirements. The two systems will compare a refrigeration/reheat system with a desiccant system coupled to a refrigeration system.

|

|||||

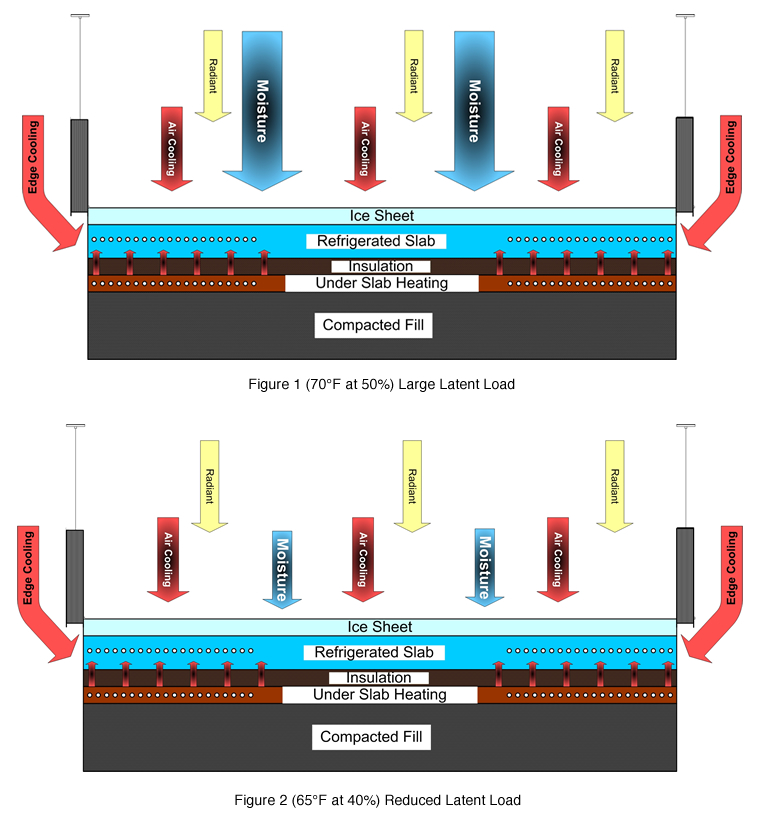

| Application Description: The cooling energy provided to the ice sheet is absorbed by three energy sources as described in the estimated flow diagram below. 15% of the energy is going to the insulated under floor heating system, 10% to the edge of the slab, 40% is cooling the air boundary layer (dependant on radiant or lighting loads) above the ice sheet, and the remaining 35% energy is freezing water vapor out of the air. |

||

|

||

| It is important to understand that humidity is driven by differential vapor pressure. Air with a higher vapor pressure (High Humidity) tries to equalize with air of low vapor pressure (Low Humidity). The boundary layer of air close to the ice sheet is cooled to a low temperature which will have a low vapor pressure. This differential pressure provides a strong motive force to draw moisture from other areas of the arena directly to the cold surface of the ice sheet. As the high humidity air is cooled as it approaches the ice sheet, fog and condensation result increasing the moisture (Latent) load on the ice sheet. By reducing the arena humidity we can reduce the energy required by the ice surface and allow the surface to maintain a better ice condition. |

| Click here for page two of NHL Standards article. |

|

||||

| © Copyright 2021 - Climate by Design International, Inc. (CDI) |