|

|

| Advanced Reactive® Desiccant Dehumidifiers for Long Term Layup and Corrosion Control | ||||

|

||||

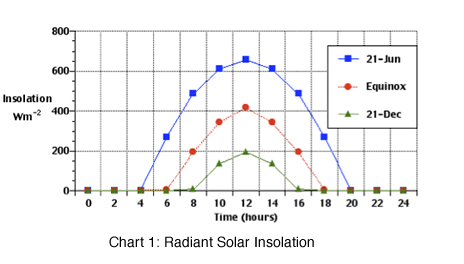

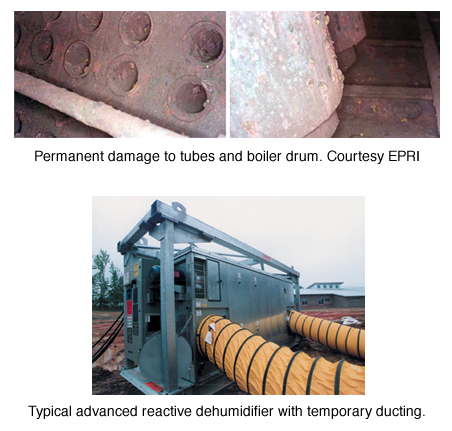

Controlling corrosion in metals is best accomplished by removing atmospheric water vapor from ambient air. The goal is to condition the ambient (air) moisture vapor pressure (dew point) to always be below the dew point temperature of the metal surfaces. To prevent moisture from collecting on the metal surfaces the ambient vapor pressure must be maintained to a lower vapor pressure than that of the surfaces. Carbon steel and other metals can oxidize when ambient dew point levels exceed the surface dew point temperature. Microscopic moisture particles in the moisture laden boundary layer will collect on surfaces as the metal cools. As more water molecules collect, visible moisture appears. This moisture can create rapid oxidation or flash rust. Other materials present from the combustion processes on the gas side of boilers and auxiliaries can also interact with moisture to form acids which can further accelerate the degradation of some metals. Typical large power plants involve tons of solid mass that react slowly (lag) to ambient atmospheric changes in temperature. Ambient weather changes can happen rapidly: the typical daily swings in ambient temperatures can be 30°F or more. Ambient humidity swings can also be extreme. The peak of the ambient temperature generally happens in the afternoon when net solar radiation gains are the largest. The large mass of metal surface reacts slowly to air temperature changes because of the arrangement of the structure and specific heat of the materials. The night convective cooling effect can remove energy from the materials and the daytime convective heating effect can warm the materials. Radiant energy during the daytime can also warm the exposed surfaces. This net energy balance can provides a cool surface that can act as a condenser. When the vapor pressure temperature is higher than the surface vapor pressure temperature of the metal, corrosion and pitting can result.

This net energy balance can provides a cool surface that can act as a condenser. When the vapor pressure temperature is higher than the surface vapor pressure temperature of the metal, corrosion and pitting can result.

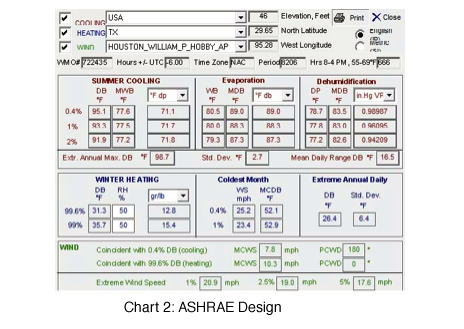

Chart 2 above shows ASHRAE design conditions for Houston's Hobby Airport. The peak ambient dew point for a dehumidification application shows 78.7 °F: any surface that is below that temperature will collect moisture as it acts as a condenser. Controlling the air dew point below that level is critical to avoiding moisture related corrosion.exposed surfaces. Elevated humidity levels on the combustion side of the systems can also react with residual process deposits to form acids. The industry to date has used relative humidity % RH as a control point to reduce the effects of atmospheric humidity. It is more accurate to protect the surfaces by allowing the controlled ambient dew point to always be below the coldest surface temperature. A differential dew point between the ambient air and the metal surfaces will reduce or eliminate this corrosive effect. "The most important factor in atmospheric corrosion, overiding pollution or lack of it, is moisture, either in the form of rain, dew, condensation, or high relative humidity (RH). In the absence of moisture, most contaminants would have little or no corrosive effect." |

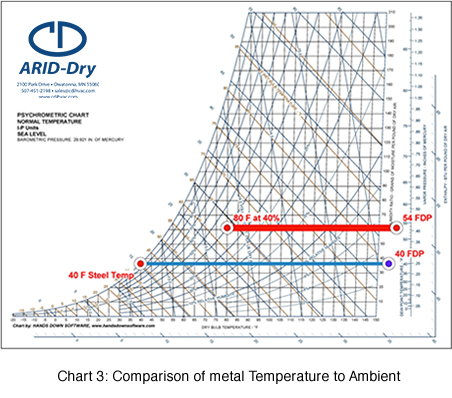

The challenge of controlling the internal moisture levels is the size and complexity of typical generating plants. Generating plants can expose the structures to variable temperatures; from a sub-basement feed water system to external flue gas treatment devices. The structure can have a variety of structural temperatures, thereby making it difficult to have one dew point set point that would provide protection for all components. The areas located in cool areas could see average summer steel temperatures of 50° to 60° F Degrees while components located in higher areas or external to the plant, might be exceed 75° F. During cold weather months components connected or exposed to the outdoors could see average steel temperatures of 0° to 40° F. The specific vapor pressure of air at the recommended 40% RH at normal heating temperatures is very different. (See Chart 3). The chart shows a steel temperature of 40° F with an interior air condition of 75° to 80° F at 40% RH. Both of those air readings show a dew point condition higher than the steel, there will be condensation in this example Average steel temperatures will vary with atmospheric and environmental forces over the layup period resulting in an elusive thermal equilibrium. Dew point control and measurement can provide a more accurate predictor for corrosion prevention. Structuring a dew point monitoring system that will provide a set point based on the coldest surface temperatures will provide consistent and predictable corrosion prevention.

Generating plants can be protected by proper conditioning of both the combustion/gas side and the steam side of the system. By reducing the dew point of the air in contact with steel surfaces with an advanced reactive desiccant system, the dew point can be adequately controlled to eliminate the moisture reaction on the coolest surface of the pressure generating system. Typically the wet side, turbines, super-heaters and the boiler wet side can be controlled by one system(s) and the gas side including the boiler, economizers and baghouse can be conditioned with a separate dehumidification system(s). Sizing the system is done by calculating the cubic volumes of the spaces and piping to be conditioned. Additional capacity must also be provided to account for leakage rates to ambient. Advanced Reactive Desiccant systems can be sized to provide long term protection for components through proper sizing and application. References: Kingston Technical Software, Corrosion Engineering principles and practice. |

|||

|

||||

| © Copyright 2021 - Climate by Design International, Inc. (CDI) |