|

|

| Drying Skating Equipment, Reducing Mold and Mildew in Locker Rooms. | ||||||

|

||||||

Moisture is a fact of life in locker rooms from high school sports through major arena sporting events. The shower room, equipment and storage areas are ripe with smells and odors from showers, damp equipment and uniforms. The smells and odors are created by molds and bacteria that are thriving in the high humidity environment of the locker room. Mold spores occur naturally in the environment. The spores proliferate on surfaces in areas of high humidity. Bacteria growth is similar. Both mold and bacteria growth can be reduced or eliminated by removing the one of the key factors needed for growth. Studies have suggested that most mold growth can be minimized by controlling relative humidity to levels below 40% RH. Modern locker rooms have utilized dry desiccant dehumidification to maintain humidity levels for the locker rooms. By reducing the moisture vapor pressure in the locker rooms, the facility and skating equipment can dry out after high activity. The low dewpoint dry air will reduce or eliminate growth of mold spores while allowing the room to dry and moisture in the equipment to evaporate. The application of a desiccant dehumidifier is appropriate to this application because of its ability to remove large amounts of water vapor form the ambient air. This provides the low vapor pressure necessary to draw moisture out of structures and equipment. By providing very dry ventilation air we can "Deep Dry" a facility to draw water out of the building, materials and equipment. Maintaining just temperature control can cause the indoor humidity to rise. Internal uses such as the showers, hot tubs and other facilities can add water vapor to elevate humidity. Current codes require increased amounts of ventilation air which must be treated properly to control humidity. ASHRAE (American Society of Heating, Refrigeration and Air Conditioning Engineers) recommends standards that have adopted by most building codes in the United States. Typical Required Outdoor Air Ventilation Rates recommended are .5 SCFM per square foot of locker and dressing room area. As an occupied room the conditioned air can be circulated at normal conditions of 70 to 75F at 45% to 55% RH. When the room is Un Occupied the locker room and or the equipment storage area can be isolated from and outside air in the HVAC unit. |

The Desiccant Unit is then energized to dehumidify the space and provide the low vapor pressure air necessary to dry the room and equipment. To improve the locker room humidity a desiccant dehumidifier can be installed to deep dry the facility by lowering the humidity of the locker room. The main target of this process is to promote a healthy, dry environment by reducing humidity to keep uniforms, equipment and the interior facility dry. Odors from mold and growth from mildew are reduced or eliminated. The unit can be controlled by a simple humidistat to maintain the humidity and deep dry the locker during nighttime or low use periods.

|

|||||

A desiccant system can be added to condition most facilities. The Dehumidification unit Model SDH-126 rated at 2,000 SCFM is a perfect solution for most locker rooms. Manufactured by CDI, the unit is a packaged system which uses electricity or natural gas to reactivate the rotating desiccant wheel. The desiccant wheel rotates slowly picking up moisture from the process air stream and transferring the moisture as a vapor into the reactivation air stream where it is exhausted outdoors. |

The low humidity discharge air is recirculated in the equipment storage area and continues to depress the vapor pressure. This low dew-point provides the vapor pressure differential necessary to evaporate moisture from the building and the equipment. This system differs greatly from a typical cool reheat system as the desiccant can reduce ambient moisture content well below the freeze point of liquid water. Desiccants remove water in the vapor phase. |

|||||

|

||

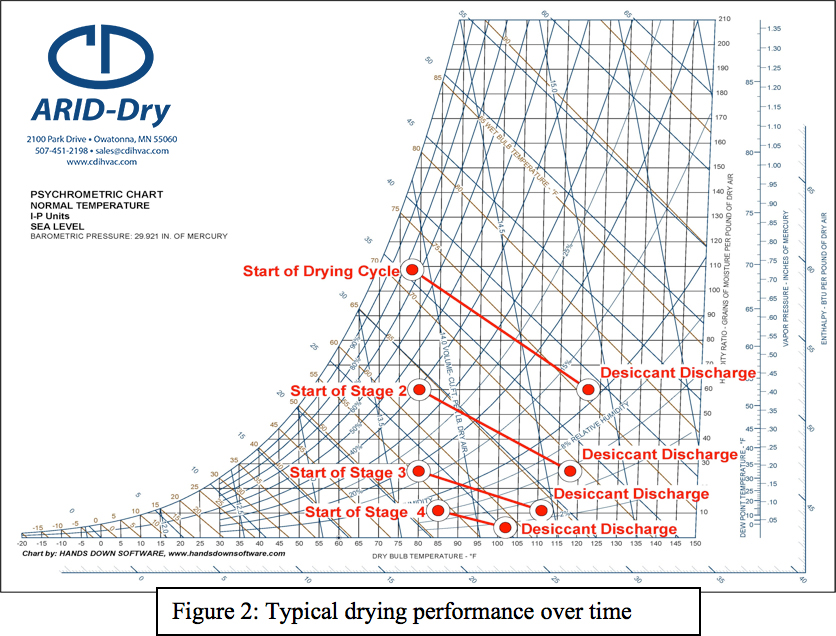

Final temperature and humidity level is always determined by environmental factors, room integrity, recirculation system and quantity of wet equipment in the space. Stage 1 describes the start of drying when the wet room is isolated for the HVAC system. This is an estimated start for the drying cycle. Stage 2 san happen rapidly based on the air change rate, equipment loading and space conditions. Stage 3 and 4 represent advanced balance between the dryer capacity and residual water in the space and equipment. Todd Bradley, Desiccant Dehumidifier Application Specialist |

|

||||

| © Copyright 2021 - Climate by Design International, Inc. (CDI) |