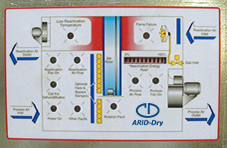

< Our reactivation burner flame safeguard system is an industrial Honeywell R7895A instead of a commercial-or residential style "ignition module." The standard gas train on gas-fired units is an ANSI type, and includes inlet regulator, automatic main and pilot valves, an electronic modulating valve, in addition to safety manual valves.

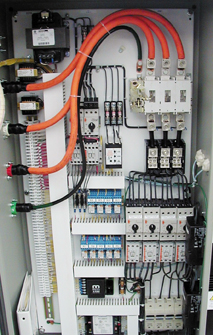

Electric heater banks with individual circuit breaker protection.

< Wiring to industrial terminal strips makes for easier connection and troubleshooting.

< A full-perimeter sprocket with a #40 molly chain drives our desiccant rotor. This is more durable than any other system on the market.

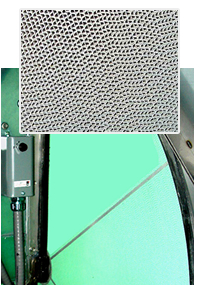

< Stabilized silica gel is permanently bonded to a low specific-heat substrate for long-lasting dehumidification performance at maximum efficiency. The desiccant rotor rim and cassette are Stainless Steel for durability and strength.

< Our desiccant rotor seals are dual-contact seals, designed to extend the life of the unit. This is the most durable seal in the industry.

|