| |

Water filtration and wastewater treatment facilities commonly suffer from corrosion,mold, mildew, and poor reliability of electronic devices caused by condensation.This is especially true in northern climates where very cold influents are prevalent.

Cold influent pipes sweat during elevated ambient humidity. By controlling the humidity of the air surrounding these cold pipes, condensation is eliminated.

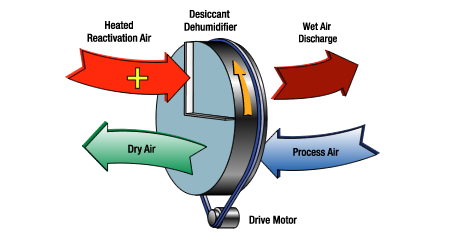

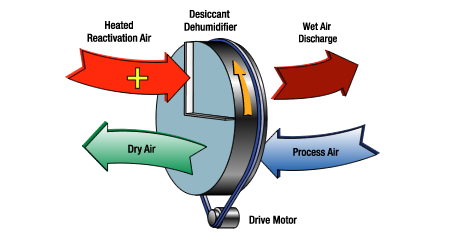

Why Use Desiccant Technology?

Water filtration and wastewater treatment plants commonly experience influent temperatures of 35-50°F. This means that if the humidity in the pipe galleries exceeds 35-50°F dewpoint, the pipes will sweat. By depressing humidity to a dewpoint about 5° below the temperature of the coldest pipe, condensation is prevented.

Refrigerant and chilled-water-style dehumidifiers are adequate for noncritical dehumidification applications, such as indoor swimming pools and building air quality. When the required level of dryness approaches about 45°F dewpoint however, "cold-coil" systems begin to experience frozen condensate, and in the case of DX systems, risk compressor failure from inadequate load and poor oil return.

Smart Dehumidifier Control

Humidity control level is directly dependent upon the coldest surface within the facility. By continuously comparing humidity to a representative pipe surface temperature, ARID-Dry desiccant dehumidifiers actively reduce the space dewpoint to a level required to prevent sweating.

In addition, our proprietary microprocessor prevents the room humidity from ever exceeding a set value. This is of benefit in the event of a temperature sensor failure, or during times when the pipe with the temperature sensor is warm. Space humidity is maintained at a constant dewpoint.

The controller also minimizes reactivation energy. Preventing overheating - even in the event of plugged filters - insures safe operation. In addition, unlike units with single-point reactivation controls, full dehumidification performance is available, even on cool days. |

|

FEATURES:

- Double-wall insulated weatherproof construction is suitable for indoor or outdoor mounting.

- Optional curb mounting allows bottom supply and return air ducts within the curb.

- Sizes from 600 to 40,000 CFM meet virtually any facility's needs.

- Top, bottom or side duct configurations allow flexible installation and location possibilities.

- Optional outside air package may eliminate the need for a separate air supply unit.

- Standard pleated filtration on process and reactivation airstreams keeps unit and space clean.

- Architecturally pleasing silhouette and optional color coating insure aesthetic value and years of durability.

- Our standard unit includes a microprocessor controller for reactivation rate and safeguard functions, and also for heating and cooling functions if these options are present. Terminal strip connection points are included for customer use for alarming, monitoring, and for communication with a building management system. (Our microprocessor is a BAC-Net compatible device, and requires a gateway device to communicate.)

- Each unit is ETL Listed and approved as a unit. Every item shipped carries a full ETL approval including all options in compliance with the current mechanical code.

- Our microprocessor reactivation controller maintains a constant burner output temperature. In addition, modulating via a reset schedule minimizes energy use. Full rated performance is available in cool weather because it is not necessary to limit the firing rate as other manufacturers do.

- Our units use combination circuit breaker/overload/starters for fan motors. This eliminates the need for spare power fuses, and saves the customer downtime because, if an upset occurs, a simple reset will bring the unit back on line.

- Stabilized silica is gel permanently bonded to a low specific heat substrate for long lasting dehumidification performance at maximum efficiency. The desiccant rotor rim and cassette are stainless steel for durability and strength.

- Filters provided are minimum 30% efficient industrial pleated-style to insure a clean desiccant rotor. Additional filtration is available.

- Our desiccant rotor seals are dual-contact, Viton extruded seals, designed to last for the life of the unit. This is the most durable seal in the industry.

- Built in the U.S.A.

ARID-Dry application specialists are available to help you and your engineer select the proper model. Our moisture load analysis takes the guesswork out of dehumidifier sizing. Over 30 years of experience with desiccant technology prevents many common application mistakes. |

|