Technical:

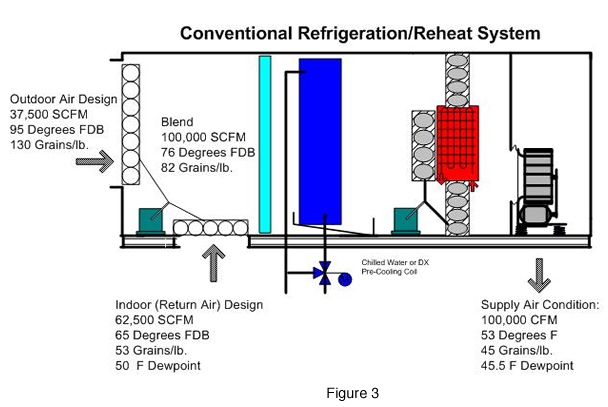

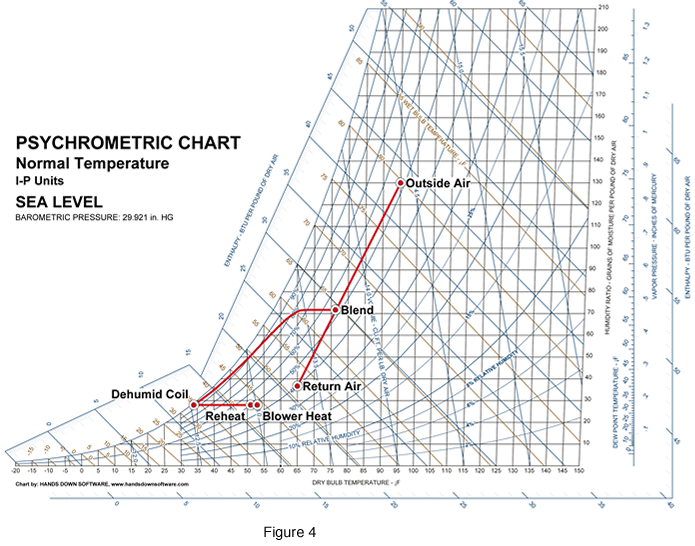

To properly maintain humidity levels we need to estimate moisture loads during occupied events and determine the outside air requirements. We will use an example of a 20,000 seat arena with a mechanical room in each quadrant serving approximately 25% of the space. For the purpose of this example we will compare a refrigeration system designed to maintain 65°F at 40% RH (36.6 Grains of Moisture/Pound of Dry Air) with a desiccant system designed to maintain 65°F at 40% (36.6 Grains of Moisture/Pound of Dry Air). Each system provides a 12°F and 8 grain depression to accommodate internal loads. For normal application each quad will use 100,000 SCFM (Standard Cubic Feet Minute @ 70°F) total air with 37,500 SCFM of outside air based on 7.5 SCFM per person. The total arena will use approximately 400,000 SCFM with 150,000 SCFM of outside air. The system below would be located in each quad. The diagrams below will show dew-points and Grains/Lb in lieu of relative humidity. Relative Humidity can be confusing with multiple temperature changes. |